Service

We are not only one of the best thin film materials producer,

but also provide PVD technology consulting services for free.

Service

We are not only one of the best thin film materials producer, but also provide PVD technology consulting services for free.

1)Bonding

Our sputtering target bonding process provides all metal bonding to affix sputtering targets to backing plates for systems which do not utilize a bolt-on target assembly. The purpose of the bonding is to provide the following functions during plasma deposition:mechanical strength, electrical conductivity and thermal conductivity.

This process utilizes a series of thin metallic layers to provide adhesion, diffusion barrier and wetting layers to the target and backing plates. The most common solder for metallic bonding of sputtering targets to backing plates is high purity indium.

2)Custom Alloys

We can make alloy materials according to customer's requirement. We have a large number of melting furnaces, which enables customers to meet small batch or large batch alloy material needs. In China, we have served many customers, including school laboratories, research centers, to meet customers' personalized alloy material needs. Meeting the needs of our customers is always our first priority.

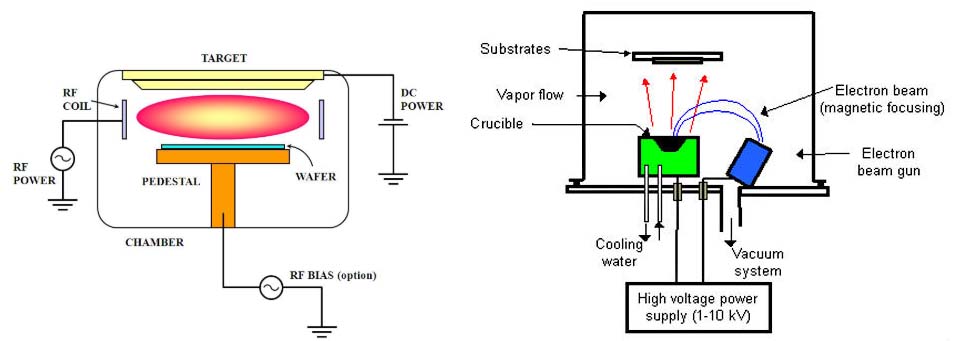

3)PVD Consulting

We are not only provide our customers with a variety of vacuum coating special film materials, we also provide vacuum coating technology consulting services. With the development of material surface treatment technology and the update of material surface treatment equipment, PVD technology can deposit metal and alloy film, compound film, polymer film, ceramic film, semiconductor film and so on. PVD technology can realize the deposition of different materials and improve a variety of properties of materials, such as wear resistance, corrosion resistance, decoration, conductivity, insulation, photoconductivity, piezoelectric, magnetic, lubrication, superconductivity and other properties. We provide professional consultation for customers in the process of coating problems, to provide customers with one-stop solution for vacuum coating.And the most important thing is that the solution for your issues is free, as it is our duty to help you.